For those who wield knives with precision and finesse, understanding the intricacies of blade geometry is paramount to unlocking sharper edges and improved efficiency in the kitchen. Whether you’re a seasoned chef or a culinary enthusiast, mastering the art of optimizing blade geometry can elevate your cooking experience and take your skills to new heights. In this comprehensive guide, we’ll delve into the world of advanced SEO-focused article writing techniques, exploring the nuances of best knife edge geometry, kitchen geometry, and paring knife diagrams to help you become a master of the cutting edge.

At What Angle Is a Blade Sharpest?

The ideal angle for a sharp blade depends on various factors, including the type of knife, its intended use, and personal preference.

- Kitchen Knives: Typically, kitchen knives are sharpened to a 15 to 20 degree angle, with some high-carbon steel knives requiring a slightly sharper edge at around 12 to 15 degrees.

- Pocket Knives: Pocket knives usually have a coarser edge, ranging from 20 to 25 degrees, making them suitable for everyday carry and general-purpose tasks.

- Outdoor Knives: Outdoor knives, such as those used for hunting or camping, may require a sharper edge at around 10 to 15 degrees to ensure effective cutting and durability.

Some notable manufacturers, like Shun and Global, offer high-quality knives with precision-ground edges, often sharpened to a 15-degree angle.

When it comes to sharpening your own blades, consider investing in a whetstone or sharpening stone specifically designed for your knife type. Regular maintenance and honing can help maintain a razor-sharp edge and extend the life of your blades.

For more information on knife sharpening techniques and tools, visit our Knife Sharpening Tips page or explore our selection of Sharpening Stones.

Remember, the optimal angle for a sharp blade may vary depending on individual preferences and needs. Experiment with different angles and techniques to find what works best for you.

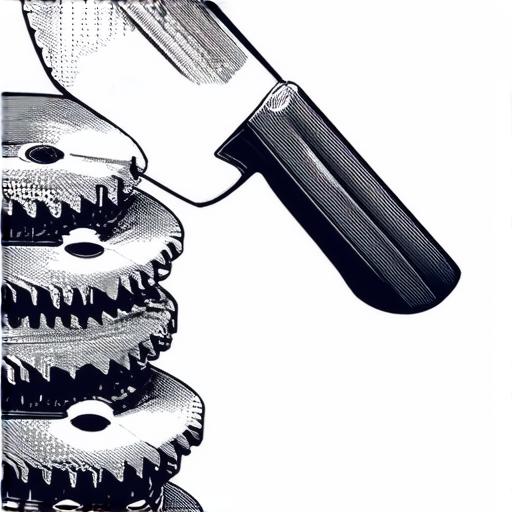

Optimal Blade Shape

The optimal blade shape depends on various factors, including intended use, personal preference, and skill level.

- Drop Point Blade: A versatile and popular choice, suitable for everyday carry (EDC) and hunting knives. Its balanced design excels in slicing tasks, meat processing, and opening packages.

- Clip Point Blade: Ideal for skinning and cleaning game, featuring a sharp, pointed tip and a curved belly for efficient cutting.

- Skinning Blade: Designed specifically for skinning animals, typically featuring a long, narrow profile and a straight edge for smooth, precise cuts.

- Tanto Blade: Characterized by its angular, triangular shape, often preferred by collectors and enthusiasts due to its unique appearance and functionality.

- Wharncliffe Blade: Featuring a flat, broad profile and a straight edge, commonly used for utility and work knives, ideal for chopping and slicing tasks.

When choosing the optimal blade shape, consider factors such as:

- Task-specific requirements

- Personal comfort and handling preferences

- Level of expertise and skill

- Material and durability considerations

At Doc’s Knife Works, we offer a variety of blades and knife designs tailored to meet individual needs and preferences. Our expert resources and tutorials provide valuable insights into knife-making, craftsmanship, and care, ensuring you find the perfect blade shape for your next project.

Choosing the Right Blade Cutting Angle

At Doc’s Knife Works, we understand the importance of selecting the correct cutting angle for optimal performance.

- General Purpose Blades: A 20-degree bevel angle is suitable for general-purpose blades, providing a balance between sharpness and durability.

- Cutting Tools: For cutting tools, a 30-degree bevel angle is recommended, allowing for efficient material removal and reduced wear on the tool.

- Surgical Blades: Surgical blades require a precise 15-degree bevel angle to minimize tissue damage and promote smooth cutting.

- Woodworking Blades: Woodworking blades benefit from a 25-degree bevel angle, enabling clean cuts and reducing tear-out.

When choosing a blade cutting angle, consider the intended application, material type, and desired level of sharpness.

- Determine the required cutting angle based on the specific task or material.

- Select a blade with the chosen bevel angle, taking into account factors like edge retention and durability.

- Sharpen the blade according to the manufacturer’s guidelines to achieve optimal performance.

By understanding the importance of blade cutting angles and selecting the right angle for the job, you can enhance your overall cutting experience and extend the life of your blades.

Additional Tips for Blade Maintenance

- Regularly inspect and sharpen blades to maintain optimal performance.

- Store blades properly to prevent damage and corrosion.

- Choose high-quality blades made from durable materials to reduce the need for frequent replacement.

Blade Sharpening Resources

For more information on blade sharpening and maintenance, visit our Sharpening Supplies page or explore our Knife Sharpening Angle Chart.

Easiest Blade Shape to Sharpen

When it comes to sharpening blades, some shapes are easier to work with than others.

- Straight Edges: Straight-edge blades are generally the easiest to sharpen due to their simplicity and lack of complex curves.

- Wharncliffe and Sheepfoot Blades: These blades feature a straight edge with a slight curve towards the tip, making them relatively easy to sharpen compared to more complex shapes.

- Military, Stretch, Delica, and Persian Blades: These blades combine a straight edge with a convex curved section towards the tip, requiring slightly more effort to sharpen but still considered relatively easy.

- Other Considerations: While these shapes are generally easier to sharpen, individual preferences and techniques may vary. Factors such as blade material, edge geometry, and personal comfort level can influence the ease of sharpening.

At Doc’s Knife Works, we understand the importance of proper sharpening techniques and recommend exploring our resources on knife-making and maintenance for further guidance.

For a deeper dive into knife-related topics, visit Blade Forums or explore the world of knife enthusiasts at Knife Planet.

We also recommend checking out Buck Knives for high-quality blades and Cold Steel for innovative designs.

Remember to always follow proper safety protocols and techniques when working with sharp blades.

What Blade Stays Sharp the Longest?

The age-old question of what blade stays sharp the longest has puzzled many a chef and outdoors enthusiast.

- Ceramic Blades: Ceramic blades have gained popularity in recent years due to their exceptional durability and ability to stay sharp for extended periods.

- High-Carbon Stainless Steel Blades: High-carbon stainless steel blades offer excellent corrosion resistance and can retain their edge for a long time.

- Stainless Steel Blades: While not as durable as ceramic or high-carbon stainless steel blades, stainless steel blades still offer decent performance and can stay sharp for a reasonable amount of time.

When it comes to staying sharp, the type of metal used in the blade plays a significant role. However, other factors such as maintenance, sharpening techniques, and usage patterns also contribute to a blade’s longevity.

- Maintenance: Regular cleaning and drying of the blade can prevent rust and corrosion, helping it stay sharper for longer.

- Sharpening Techniques: Using the correct sharpening technique and angle can significantly impact the blade’s ability to stay sharp.

- Usage Patterns: How often and how you use the blade affects its lifespan. Heavy-duty use may require more frequent sharpening.

In conclusion, while various types of blades excel in different aspects, ceramic blades stand out for their exceptional durability and ability to stay sharp for extended periods.

At Doc’s Knife Works, we understand the importance of choosing the right blade for your needs. Our expert resources and tutorials can guide you in selecting the perfect blade for your next adventure.

The Most Efficient Blade Design

In the world of knife-making, the efficiency of a blade design can greatly impact its overall performance and effectiveness.

- Single-Bladed Design: As mentioned earlier, the single-bladed design is considered the most structurally efficient for the rotor blade, boasting the greatest blade section dimensions with all the installed blade surface area in a single beam.

- Double-Bladed Design: While not as efficient as the single-bladed design, double-bladed designs offer improved stability and reduced vibration, making them suitable for high-speed applications.

- Triple-Bladed Design: Triple-bladed designs provide exceptional balance and reduced weight, making them ideal for precision cutting tasks.

When it comes to choosing the most efficient blade design, several factors come into play, including the intended application, material selection, and manufacturing process.

- Material Selection: The choice of material plays a significant role in determining the efficiency of a blade design. High-carbon stainless steel, for example, offers excellent durability and corrosion resistance, making it a popular choice for high-performance blades.

- Manufacturing Process: The manufacturing process can significantly impact the efficiency of a blade design. Techniques such as heat treatment and cryogenic tempering can enhance the strength and hardness of the blade, resulting in improved performance.

- Application-Specific Designs: Different applications require unique blade designs to optimize performance. For instance, a blade designed for chopping wood may have a thicker, heavier construction than one designed for slicing meat.

At Doc’s Knife Works, we understand the importance of selecting the most efficient blade design for your specific needs. Our team of experts is committed to helping you find the perfect blade solution, whether you’re a seasoned knife-maker or just starting out.

0 Comments